Non-isolated DC-DC Buck Converter Buying Guide

When purchasing a non-isolated DC-DC buck converter, it's essential to consider various technical and practical aspects to ensure it meets the requirements of your application. Whether you're stepping down voltage from 24V to 12V, 12V to 5V, or handling conversions from higher voltages like 48V, 60V, or 72V, choosing the right converter can significantly impact efficiency, performance, and durability. Here are some key factors to keep in mind:

How to Choose a Right Non-isolated DC-DC Step Down Converter?

Input and Output Voltage Range

The first and foremost consideration is the voltage range. It is vital to ensure that the converter can handle the specific input voltage of your power source. For example, if you are working with a 24V system, make sure the converter can accommodate the typical voltage variations (e.g., 20V-30V) that might occur due to battery fluctuations or other conditions. The output voltage should be stable and consistent, whether it's a fixed 12V or an adjustable range, depending on your requirements.

Current Rating and Power Capacity

Understanding the current rating and overall power capacity of the converter is crucial. You need to check how much current (in amps) the converter can supply to the load. For example, if your device draws 5 amps at 12V, then your converter must be rated to handle at least 60 watts of power (12Vx5A=60W). Selecting a converter with sufficient capacity ensures reliable performance and prevents overloading, which can lead to device failures or potential safety hazards.

Efficiency and Thermal Management

Efficiency is a critical parameter when choosing non-isolated DC-DC buck converter, as it determines how much power is wasted during the conversion process. High-efficiency converters (typically above 85-90%) generate less heat, which not only conserves energy but also reduces the need for extensive cooling solutions. However, even with high-efficiency ratings, heat dissipation can still be a concern. Consider the type of cooling integrated into the converter: passive cooling with heat sinks is generally quieter and more robust, while active cooling with fans can be necessary for high-power units to maintain temperature control.

Essential Protection Features

Reliability and safety are often determined by the protection features embedded in the converter. Overcurrent Protection (OCP) prevents damage when excessive current flows through the system, while Overvoltage Protection (OVP) safeguards your devices from damaging voltage spikes. Thermal shutdown mechanisms are also essential for preventing overheating, which could otherwise damage both the converter and the connected devices. Additionally, converters equipped with reverse polarity protection can protect against accidental wiring errors, making the installation process safer and more user-friendly.

Adjustability and Control Options

For applications that require more flexibility, consider converters that allow for adjustable output voltages. Some models include trimmer pots or digital interfaces to fine-tune the output, which can be especially useful if you need to power devices that require different operating voltages or precise control. On the other hand, if your needs are straightforward, a fixed output converter may suffice and could even simplify your setup.

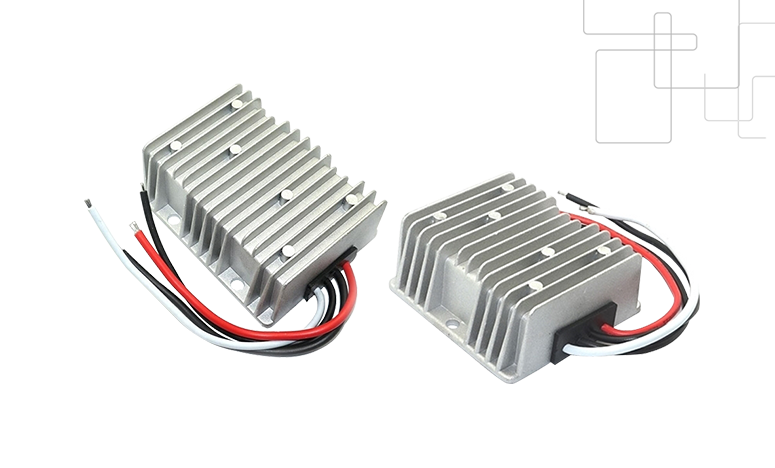

Physical Design and Form Factor

When installing a DC-DC converter, space constraints can play a significant role in your choice. Converters come in various sizes and shapes, so it's important to select a unit that fits well within your available space. Consider also the mounting options, as some models can be easily mounted on a DIN rail or secured with screws for a more stable installation. This is particularly useful in automotive, marine, or industrial applications where vibrations and movement are common.

Noise, Ripple, and Compliance

Low noise and ripple are essential, especially when powering sensitive electronics. Excessive ripple can lead to malfunction or shortened lifespans of connected devices. Therefore, it's advisable to check for specifications regarding ripple voltage, measured in millivolts peak-to-peak (mV p-p), and opt for converters with lower ripple values. Additionally, depending on your operating environment, ensure the converter complies with EMI/EMC standards to minimize electromagnetic interference that could affect other electronic systems.

Connection Options and Build Quality

The type of connectors and wiring configurations are also important. Look for converters with input and output connectors that match your setup, whether it's screw terminals, Molex connectors, or other configurations. A solid, well-built converter with robust connectors can make the installation process easier and improve long-term reliability. Furthermore, rugged designs with high-quality enclosures can better withstand harsh conditions, such as dust, moisture, or high-vibration environments.

Cost, Brand Reliability, and Warranty

Lastly, consider the overall cost versus the benefits provided by the converter. While cheaper options may be tempting, they often compromise on build quality, efficiency, or essential protection features. Investing in a reputable brand known for reliability can save you from future issues, and products backed by a good warranty often reflect a higher standard of quality. Checking user reviews and technical support availability can also give insights into the long-term performance of the product. SUCH has been selling high performance DC-DC power converters at factory prices.

Practical Use Cases

- 24V to 12V Converters: Often used in trucks, RVs, and boats to run standard 12V equipment from a 24V battery system.

- 12V to 5V Converters: Suitable for powering USB devices or small electronics from a 12V source, making it ideal for automotive or portable setups.

- 48V to 12V Converters: Common in solar power systems, electric bicycles, and other renewable energy applications where 48V batteries need to supply power to 12V systems.

- 60V or 72V to 12V Converters: Typically used in electric vehicles to power auxiliary systems or low-voltage electronics from the main battery. Considering these factors will guide you in selecting the most suitable non-isolated DC-DC buck converter for your needs, ensuring efficient and reliable power delivery across a wide range of applications.