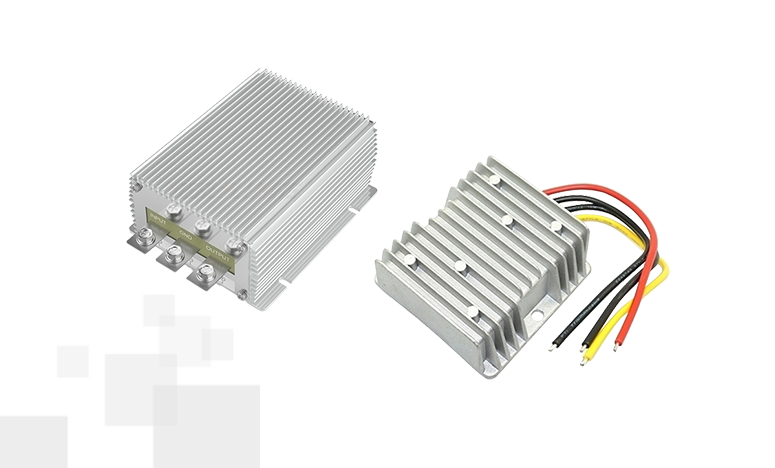

Non-isolated DC-DC Boost Converter Buying Guide

DC-DC converters are essential components in a variety of electronics, especially in systems that need voltage level adjustments. A non-isolated boost DC-DC converter (commonly known as a boost converter) is a type of DC power supply used to increase the input voltage to a higher output voltage without electrical isolation between input and output. In this buying guide, we will cover everything you need to know about selecting the right non-isolated boost module for your application.

Boost Converter Basic Components

A boost converter is a power electronics circuit that steps up (boosts) the input voltage to a higher output voltage. It works by storing energy in an inductor and then releasing it to the output through a switching process. Here are the key components of a DC DC boost converter:

- Inductor: Stores energy when current flows through it.

- Switch: Typically, a MOSFET or IGBT controls the inductor's current flow.

- Diode: Allows current to flow only in one direction and prevents reverse current flow.

- Capacitor: Filters out voltage ripples and smooths the output voltage.

- Controller: A control circuit (usually a PWM controller) that regulates the switch timing to maintain desired voltage.

The lack of isolation in a non-isolated step up converter means no physical separation (like a transformer) between the input and output. This makes them simpler, cheaper, and more compact than isolated converters but limits them to applications where isolation isn't a safety requirement.

Key Specifications to Consider

When purchasing a non-isolated step up converter, it's critical to assess several key performance factors that determine how well the converter will fit your needs.

Input Voltage Range

The input voltage range is the span of voltages that the converter can accept and boost. Ensure that the converter you choose can handle your application's minimum and maximum input voltages. Example: If you are designing a system that runs on a 5V input but needs a 12V output, the boost converter must accept 5V input and output at least 12V.

Output Voltage Range

Look for a converter that offers a stable output voltage that matches your requirements. Adjustable models provide flexibility but may require additional components to configure. Some converters come with a fixed output voltage, which might be simpler if your system has specific power requirements. Example: A DC DC boost converter with a fixed 12V output is ideal for devices that need a steady 12V power supply, like certain LED drivers or battery charging circuits.

Output Current

The maximum output current the converter can deliver is another critical factor. Choosing a non-isolated boost converter that cannot supply enough current may lead to overheating or malfunction. Example: For a device consuming 2A at 12V, a converter with at least 2A output current capability is needed.

Efficiency

Efficiency is the ratio of output power to input power, typically expressed as a percentage. High-efficiency converters generate less heat and conserve more energy, making them more desirable, especially in battery-powered or energy-sensitive applications. Typical Efficiency: 80-95%, depending on the load and design.

Switching Frequency

The switching frequency of the DC DC step up converter module affects the size of the external components (such as inductors and capacitors) and the overall efficiency. Higher frequencies allow smaller inductors and capacitors, resulting in a more compact design, but they may also generate more electromagnetic interference (EMI). Common Switching Frequencies: 100 kHz to 1 MHz.

Ripple and Noise

Ripple is the small residual periodic variation in the output voltage, while noise refers to unwanted signals that may interfere with other parts of the system. Depending on the sensitivity of your application, you may need to opt for converters with low ripple and noise. Ripple and Noise Requirements: Sensitive devices like RF systems or high-precision analog circuits may need ripple values below 50mV.

Thermal Performance

Heat dissipation is an important factor to consider, especially for high-power converters. Look for converters with good thermal management features such as built-in heat sinks, external heatsink compatibility, or efficient PCB layout that improves heat dissipation.

Size and Form Factor

The physical size of the DC DC boost converter is important in applications where space is limited. Check if the dimensions meet your enclosure and PCB design constraints.

Choosing the Right Step Up Converter for Specific Applications

Different applications demand specific features from a DC DC step up converter. Below are some common application scenarios and considerations:

- Battery-Powered Devices: In battery-operated devices like smartphones, tablets, or portable power banks, power efficiency is paramount to prolong battery life. A highly efficient boost converter (90%+) is ideal, with low standby current and minimal heat generation.

- LED Drivers: LEDs are current-driven devices that require a constant voltage or current. In applications like automotive lighting or display backlighting, you need a boost converter with a stable output and minimal ripple to avoid flickering.

- Renewable Energy Systems: For solar power systems, where you might need to step up the voltage from a solar panel to charge a battery or power an inverter, choosing a boost converter with high efficiency and low thermal output is critical to ensure energy isn't wasted as heat.

- Industrial Automation: In industrial settings, reliability and robustness are critical. DC DC converters with protection features (overvoltage, overcurrent, thermal shutdown) and long-term durability are ideal in automation systems, motor controllers, and sensor interfaces.

- Consumer Electronics: Portable electronics, such as cameras, drones, or wearable devices, often need small, lightweight converters. Focus on compact, lightweight designs with high efficiency to minimize heat and prolong battery life.

All in all, choosing the right non-isolated DC-DC boost converter requires a balance between input and output voltage requirements, current capacity, efficiency, and application-specific needs. By understanding the key specifications, such as voltage range, efficiency, thermal management, and protection features, you can ensure that the converter fits your project's needs.