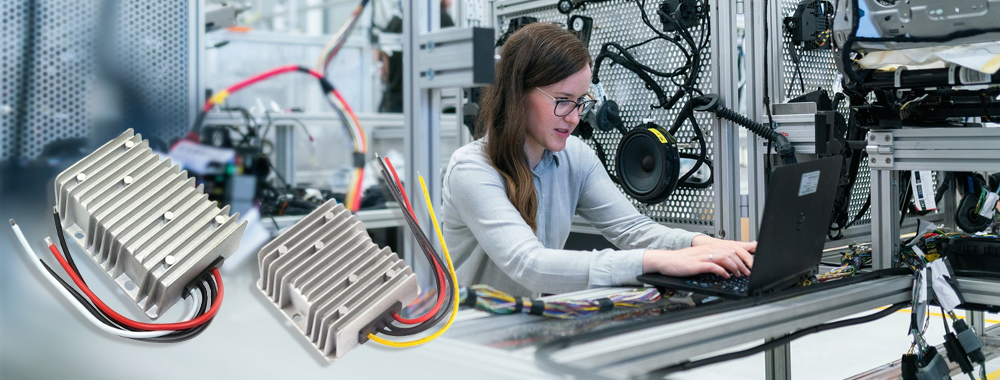

Non-isolated DC-DC Boost Converter Solutions

Case Study 1: Welding Robots in Automobile Manufacturing Workshops

Background: In the welding workshop of a large automobile manufacturer, their robot system is mainly powered by 12V power supply to reduce overall wiring and save costs. However, the welding mechanism and servo motor require higher voltage support to provide sufficient driving force and stable output. The traditional method is to provide a separate power supply for each system, but this increases the complexity of power management and wiring. In addition, the maintenance cost of the multi-power supply system is high, and compatibility issues may arise between power adapters, affecting production efficiency.

Solution: To solve this problem, SUCH recommended that the factory install a non-isolated 12V to 24V DC-DC boost converter on each robot, so that it can output a 24V stable power supply based on the 12V main power supply. Through the converter, the welding robot can work with a single 12V power supply while meeting the needs of 24V equipment. This solution not only reduces the difficulty of wiring, but also reduces the cost of equipment maintenance and replacement, and improves the stability of the production line.

Outcome: After installing the DC-DC boost (step up) converter, the overall operation of the welding robot system has become more stable. Factory feedback data shows that the maintenance frequency of the robot system has been significantly reduced, and the work efficiency has increased by more than 15%. This solution effectively simplifies the factory's power management, improves production efficiency, and saves maintenance costs.

Case Study 2: Solar Energy Storage System

Background: A distributed solar system installation company mainly provides solar solutions for remote areas or self-sufficient households. Since these users often need to rely on solar power for a long time, system stability and energy efficiency become key requirements. Usually, the battery energy storage unit selected by users has an output voltage of 24V, but in some cases with high power demand, such as inverter input or high-power load requirements, a voltage of 48V is required. For this reason, users need an efficient DC-DC boost converter to achieve voltage boost and ensure stable operation of the entire system.

Solution: In response to the needs of this user, it is recommended to use an efficient 24V to 48V non-isolated DC-DC step up converter to meet the voltage boost requirements of solar systems in remote areas or self-sufficient households. This converter can stably increase the output voltage to 48V when the input voltage is 24V, ensuring the normal operation of high-power loads or inverters, thereby improving the stability and energy efficiency of the entire system.

The boost converter should have high conversion efficiency, and it is generally recommended to choose products with an efficiency of more than 90% to reduce energy loss and extend battery life. At the same time, the load adaptability of the converter should be considered to ensure that it can operate stably under different load conditions and avoid voltage fluctuations caused by load changes. In addition, choosing a DC-DC power converter with functions such as overload protection, short-circuit protection, and temperature protection can further improve the safety and reliability of the system.

In terms of installation, it is recommended to place the boost converter as close to the load end as possible to reduce the voltage drop caused by line loss. At the same time, reasonable wiring and selection of cables of appropriate specifications will help improve the overall performance of the system.

Outcome: After deployment, the user's solar energy storage system can effectively utilize the 24V battery output to achieve stable operation of 48V equipment, reducing system losses. The system's maintenance costs are greatly reduced, and the overall operational stability and reliability are improved.

Non-isolated DC-DC Buck-Boost Converter Solutions

Case Study 1: LED Lighting System

Background: A manufacturer specializing in indoor and outdoor lighting solutions has major customers including shopping malls, hotels and home users. The user hopes to achieve a more flexible power supply design in its newly developed LED lighting products to adapt to different power input conditions and improve product compatibility and reliability. The user's product line includes LED lamps of various power levels, requiring the power supply system to adapt to different input voltages and provide a stable 12V output.

Solution: To meet the needs of the user for its newly developed LED lighting products, a 9~36V to 12V non-isolated DC-DC buck-boost converter can be used as a power supply solution. The converter can flexibly adapt to the input voltage range to provide a stable 12V output for LED lamps under various power supply conditions. With this solution, users can ensure compatibility and reliability in different power supply environments, whether it is from shopping malls, hotels or home users with multiple input voltages (such as 9V, 12V, 24V or 36V).

The main advantages of this non-isolated DC-DC buck-boost converter are its high efficiency and stability. Regardless of the fluctuations in the input voltage, the converter can automatically adjust the output to ensure that the LED lamp always receives the required 12V voltage. This feature significantly improves the reliability of the product in different application scenarios and reduces the risk of flickering or damage to the lamp due to unstable voltage. In addition, due to the optimized design of the converter, energy loss is reduced, further improving the efficiency of the overall system.

Outcome: After implementing this solution, users found that the adaptability of their LED lamps was significantly improved, and they could work normally under a wider range of power conditions. The after-sales feedback of the products was also improved. Customers in shopping malls and hotels were satisfied with the performance of the lamps, and home users also felt the convenience of using them. This flexible power supply design not only enhances the competitiveness of users' products, but also opens up more market opportunities for the company, further promoting business growth.

Case Study 2: Internet of Things (IoT) Devices

Background: A company focusing on smart agriculture is committed to developing IoT devices that can monitor soil moisture, temperature and other environmental parameters in real-time. These devices usually work in the field and rely on external power sources (such as solar panels or mains electricity), and the power supply voltage may vary from 10V to 36V. To ensure the stable operation of the equipment, the company needs an efficient power management solution to convert the unstable input voltage into a stable 24V power supply.

Solution: In response to the needs of this company focused on smart agriculture, SUCH recommended 10~36V to 24V non-isolated DC-DC buck-boost converter. This step up & step-down converter can effectively handle fluctuations in the input voltage range to provide a stable 24V output. This power management solution will ensure that IoT devices can operate stably in different working environments, especially when relying on solar or mains power. By adopting efficient DC-DC conversion technology, the device can maximize available power, improve overall energy efficiency and extend the device's service life. Selecting a converter with overvoltage, overcurrent and temperature protection further enhances the reliability and safety of the system and ensures that it is not affected by environmental factors in agricultural production.

Outcome: Applying 10~36V to 24V DC-DC buck-boost converters in IoT devices helps smart agriculture companies successfully cope with power management challenges. This solution not only improves the stability and reliability of the equipment, but also significantly improves user experience and economic benefits, becoming an important part of promoting the application of IoT technology.