What is the "Efficiency" of a DC-DC Converter?

1. What is the efficiency in DC-DC converter?

Efficiency in DC-DC converters refers to how well the converter can transform input power into output power, with minimal energy loss. In simple terms, it's the ratio of the output power to the input power, usually expressed as a percentage. Higher efficiency means less energy is lost as heat, resulting in better performance and less need for cooling.

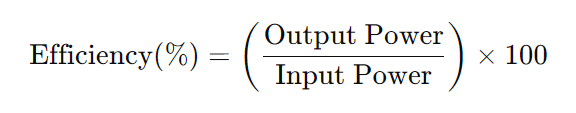

The formula to calculate efficiency is:

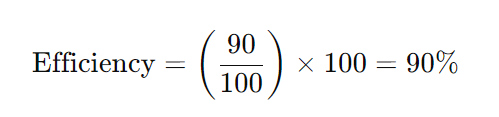

For example, if a converter has an input power of 100W and delivers an output power of 90W, its efficiency would be:

2. What affects DC-DC converter efficiency?

To improve the efficiency of DC-DC converters, one key factor is optimizing the switching frequency. Selecting an appropriate switching frequency helps balance performance and losses. Lower switching frequencies generally reduce switching losses, but they require larger inductors and capacitors, making the converter bulkier and heavier. On the other hand, higher switching frequencies allow for more compact designs with smaller components but lead to increased switching losses due to more frequent transitions.

Finding the right balance is essential to achieve high efficiency while maintaining a practical size and weight for the application. Additionally, using synchronous rectification can significantly improve efficiency. Traditional rectifiers use diodes, which introduce voltage drops and power dissipation. By replacing them with MOSFETs, which have much lower conduction losses, synchronous rectification minimizes power loss in the rectifier stage, leading to higher overall efficiency, especially in low-voltage, high-current applications.

Another crucial factor in efficiency improvement is choosing the right topology and high-quality components. Different DC-DC converter topologies have varying efficiency levels. For instance, buck converters, which step down voltage, tend to be more efficient than boost converters, which step up voltage and experience additional losses. Carefully selecting the appropriate topology for a given application ensures better power conversion efficiency. Furthermore, the quality of components plays a significant role in minimizing losses. Using low-resistance inductors, low ESR (equivalent series resistance) capacitors, and low-loss transistors reduces conduction and switching losses, ultimately improving efficiency. High-quality components not only enhance performance but also contribute to the reliability and longevity of the converter, making them a worthwhile investment for achieving optimal power conversion.

3. How to improve DC-DC converter efficiency?

- Optimize Switching Frequency: Selecting an optimal switching frequency can reduce losses. For instance, lower frequencies tend to reduce switching losses but increase size and weight, while higher frequencies result in smaller, lighter designs but higher switching losses.

- Use Synchronous Rectification: Using MOSFETs instead of diodes for rectification (synchronous rectification) can dramatically improve efficiency by reducing losses in the rectifier stage.

- Choose the Right Topology: As mentioned earlier, different converter topologies offer varying efficiency characteristics. For instance, buck converters (which step down voltage) tend to have higher efficiency than boost converters (which step up voltage).

- Use High-Quality Components: Using low-resistance inductors, low ESR (equivalent series resistance) capacitors, and low-loss transistors can help minimize conduction and switching losses.

4. DC-DC converter Typical Efficiency Ranges

- Buck Converters: These typically achieve efficiencies between 85% and 95%. They are among the most efficient types of DC-DC converters because they only step down the voltage, meaning there are fewer losses compared to boosting the voltage.

- Boost Converters: Boost converters, which step up voltage, tend to have slightly lower efficiencies, typically between 80% and 90%. The efficiency loss comes from the higher voltage step-up process and switching losses.

- Buck-Boost Converters: These are a combination of both buck and boost converters and usually fall within the 80% to 90% efficiency range. Isolated Converters: These converters, which use transformers to provide isolation, often have lower efficiency compared to non-isolated types, typically ranging from 75% to 85%.

Efficiency is a crucial factor when selecting or designing DC-DC converters. Understanding the various factors that impact efficiency and knowing how to optimize them can result in better performance, lower heat generation, and longer lifespan of your systems. Whether you're designing a power supply for a portable device, a renewable energy system, or an industrial application, considering efficiency is essential for achieving the best possible results.